Aftersales & Lifecycle Support

Ensuring long-term operational success and reliability after project completion.

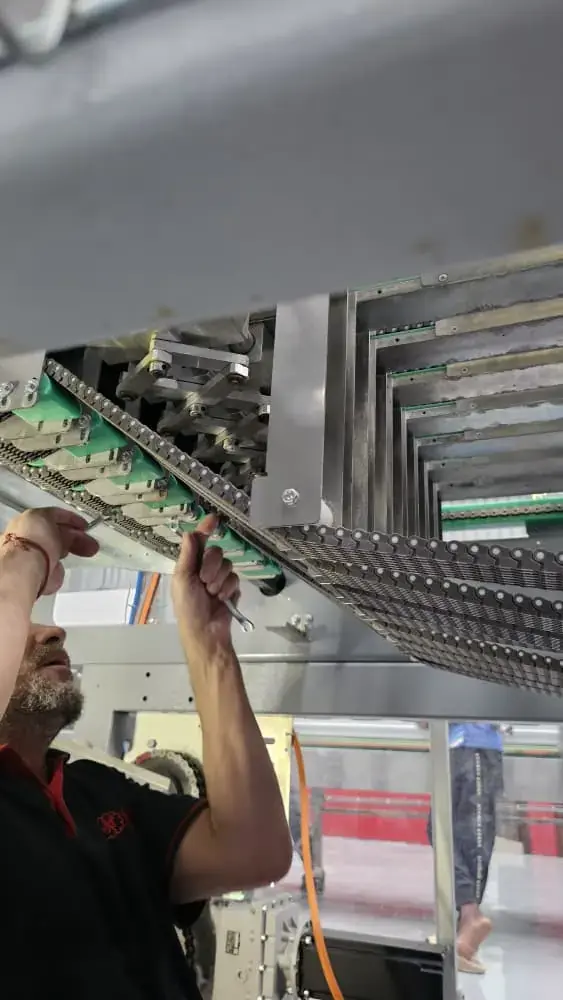

Maintenance & Technical Support

Continuous technical assistance that keeps your lines running safely, efficiently, and with predictable performance across seasons, formats, and operating conditions.

- Direct access to experienced Field Service Engineers for troubleshooting, optimization, and on-site interventions.

- Preventive and corrective maintenance plans that reduce unplanned downtime and extend equipment lifetime.

Spare Parts & Supply Chain Support

Fast, reliable access to critical spare and wear parts through a coordinated global supply network and proactive inventory planning.

- OEM spare parts sourcing that preserves machine integrity, safety, and warranty conditions.

- Optimized logistics and stock strategies that shorten lead times and protect production continuity.

Performance Optimization

Ongoing performance reviews that translate production data into concrete efficiency and quality improvements for every shift and production run.

- Process fine-tuning, line balancing, and efficiency audits that unlock hidden capacity.

- Actions focused on operational reliability, stable output, and consistent product quality over time.

Our Commitment to Clients

At our company, we focus on creating meaningful experiences for our clients. From the initial consultation to long-term support, we strive to deliver quality, reliability, and integrity at every stage of our engagement.

Trusted Client Support

We are always available to assist our clients, providing guidance, solutions, and reliable assistance whenever needed.

Integrity in Action

We uphold transparency and honesty in every interaction, ensuring our clients can trust our recommendations and decisions.

Consistent Quality

Our team delivers consistent quality and attention to detail across all projects, maintaining high standards in every aspect of our work.

Frequently asked questions

HDC is an engineering consultancy specialized in the food and beverage sector. We support beverage manufacturers with factory layout design, process optimization, utilities integration, project management, and commissioning, delivering efficient, compliant, and future-ready production facilities.

Yes. HDC has strong experience in optimizing existing facilities to unlock additional capacity without expanding the site footprint. Through precise 2D layout reconfiguration, optimized material flow, and utilities reinforcement, we integrate new production lines while maintaining operational efficiency and compliance.

HDC can manage projects end-to-end, from feasibility studies and concept design to detailed engineering, execution support, and final commissioning. This integrated approach ensures reduced risks, better coordination, and a fully operational facility delivered as a single, unified scope.

HDC has delivered projects for a wide range of beverage facilities, including soft drinks, bottled water, juices, beer, canned beverages, and ready-to-drink products. Our experience covers greenfield factories, modular plants, and existing site upgrades across multiple regions.

Yes. HDC provides hands-on on-site commissioning, system verification, functional testing, and startup support. We ensure that production and utility systems are installed correctly, perform reliably under real operating conditions, and are ready for stable day-to-day production.

Let's Build Future Together.