Rigid Packaging Production

World-Class Technology for Containers and Closures

The SACMI Advantage: Global Leadership in Packaging Founded in 1919 and headquartered in Imola, Italy, SACMI is a premier multinational group and a world-leading provider of advanced industrial technologies. Their Rigid Packaging division is the global benchmark for end-to-end production systems, specializing in high-performance, sustainable solutions for the beverage and packaging industries. As a strategic partner and solution provider, we integrate SACMI’s elite technology to transform your production concept into a high-efficiency industrial reality.

A. Injection Molding Technology for PET Preforms

We utilize high-cavity injection platforms engineered for the most demanding industrial environments.

- Circular Economy Ready: Systems are optimized for 100% PET handling, maintaining maximum clarity and cycle speeds while supporting sustainability targets.

- High-Speed Output: Advanced toggle designs and robotic extraction ensure industry-leading cycle times for maximum daily volume.

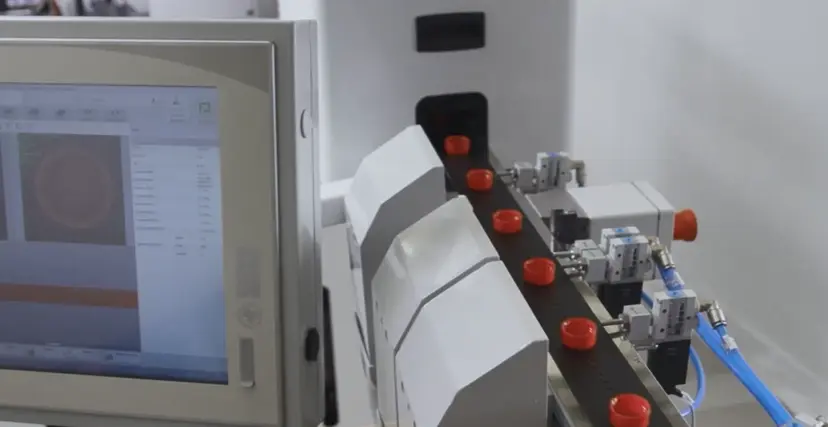

- Digital Quality Assurance: Integrated AI-driven vision systems monitor preform dimensions in real-time to ensure zero-defect manufacturing.

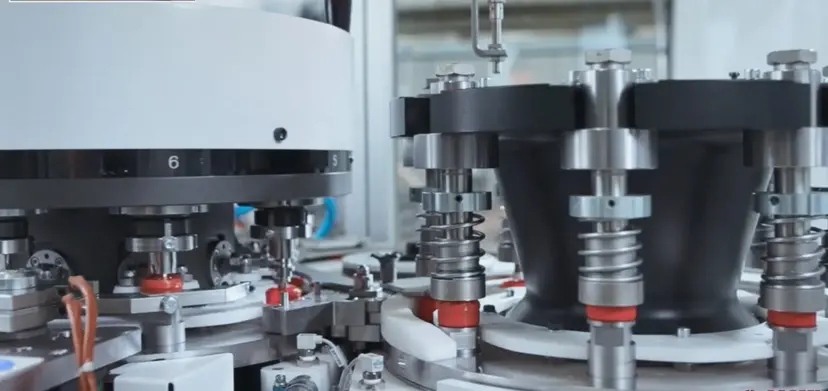

B. Continuous Compression Molding (CCM) for Plastic Caps

As the undisputed world leader in closure technology, this system offers superior quality and dimensional stability at a fraction of the cost of traditional injection.

- Energy Leadership: This technology consumes up to 35% less electricity per closure, directly improving your operational margins.

- Regulatory Compliance: Fully compatible with the latest light weighting and tethered cap standards.

- Thermal Stability: Lower process temperatures reduce material stress, ensuring a perfect seal every time.

C. Metal Cap & Closure Systems

Expanding beyond plastics, we provide advanced technologies for metallic closures, suitable for glass and aluminum containers.

- Diverse Application: Specialized systems for Crown corks, aluminum screw caps, and twist-off closures.

- High-Speed Lining: Precision lining and folding technologies ensure consistent airtight seals for carbonated and vacuum-sealed products.

- Advanced Decoration: Integrated systems for high-resolution metal printing and coating to enhance brand presence.

Engineering Value: Integrated Neck & Closure Design

Precision at the Interface: Our consultancy specializes in the technical synchronization between the preform neck and the closure. By engineering the container and the cap as a single integrated system, we eliminate leakage risks, optimize material usage, and ensure a flawless consumer experience.

Let's Build Future Together.